Tin Tức

One day internship at ‘Atelier’ with the Kudoke brand

It would be easy to have an idea for an article, but until I sat on the train to Dresden, I still did not know where to start.

Mục Lục

Empty

During a business trip to Europe in early September, in addition to participating in the Geneva Watch Days event, my schedule included a visit to the workshop of GPHG award- German winning artisan – Mr. Stefan Kudoke. Landed after a 12-hour flight from the capital Hanoi, Frankfurt welcomed me with light rain and a pleasant autumn weather. I moved to the City Central Station to take the train to Dresden. As usual, I rewarded myself with a familiar double espresso and my favorite song by The Beatles – Norwegian Wood.

On the train to Dresden, my mind was still a blank paper. Honestly, unlike usual, I still do not know what questions I would have asked or what the main topics when I met Mr. Stefan Kudoke again. These endless thoughts made me fall asleep without even realizing it. In the dream, the image of Mr. Günter Blümlein rebirthing the A Lange & Söhne brand – the brand considered the most prestigious in Germany at the present time appeared clearly and realistically as I attended the event in the year 1994 at Dresden Castle. And I knew the place to go before meeting the Kudoke brand was “Royal Palace” (Residenzschloss) or Dresden Castle / Royal Palace.

Mr. Günter Blümlein reborn the A Lange & Söhne brand at Dresden Castle/Royal Palace in 1994

Although, Dresden that afternoon was raining heavily, it did not stop me from going to Dresden Castle – a majestic palace and now a museum with large auditoriums, containing many artifacts. There are many wonderful things that made from ivory, silver, gold, amber and precious stones, etc. But what attracted my attention were the armor, the hundreds year old-carved weapons, extremely sophisticated engraving and finishing, are displayed in solemn positions.

I wonder why items that only served a specific purpose are made so elaborately and with so much effort?

Images from the author himself

Well, are not watches just the tools to measure time? There are some classic watches that have been around for decades, even hundreds of years, and have become treasures, carefully kept by people from generation to generation. So what makes a timepiece made by artist Abraham Louis Breguet, or by artist George Daniels, still so attractive and with such timeless beauty? How can watches be appreciated after many years, so that many generations will come and admire them like I am right now. I suddenly smiled.

Perfection – that is the answer to the topic of the meeting with the Kudoke brand

Nowadays, watchmakers also know how to put soul into their work. There are those who choose to create their own watch dial, while others start by creating a movement or renovating a classic watch case in a modern way. And there are people like Mr. Stefan Kudoke, who creates a highlight for the work by applying the finishing techniques that he is most proficient in on both the dial and the movement. The Kudoke brand has two outstanding works with classic designs: Kudoke 1 and Kudoke 2. Both models marked a clear difference from previous watches of the Kudoke brand in both design and quality, finish and price. The Kudoke 2 watch had a memorable launching year when it won the Petite Aiguille category – the category for watches priced under 10,000 CHF – at the Grand Prix d’Horlogerie de Genève (GPHG) 2019.

Although Sir Stefan Kudoke, unlike many of his colleagues, does not come from a family with a long tradition of watchmaking, he has devoted almost his entire professional career to watchmaking .After completing his apprenticeship at age 21, Mr. Stefan began working for the famous Glashütte Original watch factory in Glashütte. Just a year later, he received his Master Craftsman Certificate. After “going far to return”, specifically working as a craftsman for the Breguet, Blancpain and Omega brands, Mr. Stefan Kudoke decided to realize his long-cherished dream. Artist Stefan and Mrs. Ev Kudoke began their watchmaking journey.

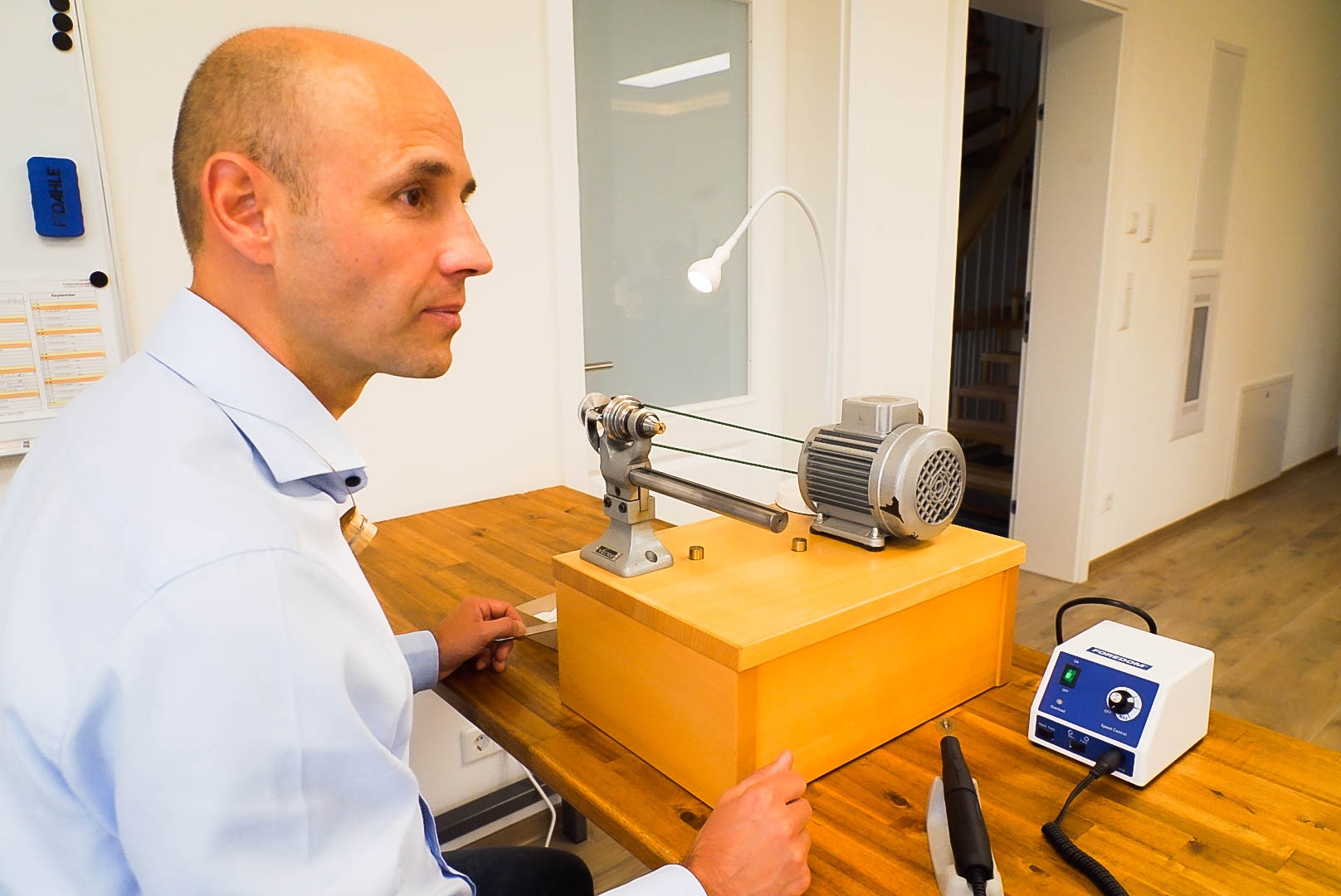

I went to artist Stefan’s watch workshop in the morning after the tour of the royal palace. It was truly a beautiful, neat and tidy watch factory located in the peaceful village of Weifa with only about 700 inhabitants. Today is the third day Weifa has had drizzle, the weather was cool, fresh and extremely refreshing. Kudoke’s headquarters is fully equipped with the machineries and necessary tools to complete a watch. The artisans here welcomed me with many friendly and affectionate smiles.

Sir Stefan and Mrs. Ev Kudoke are simple, humble and gentle people. They both took me to visit “Altelier”, and I even tried my hand at completing the details on the watch movement. However, watchmaking is similar to the sentence “Cooking is easy, but making delicious dishes is not simple”. And I had a memorable day as an “intern” at the factory. There are many complex techniques for finishing a Kudoke watch, I chose three methods that I love and regularly write about the finishing methods: Engraving, Ratchet wheel, and Anglage.

Engraving

Today, Kudoke’s product line essentially consists of two collections: the HANDwerk line and the KUNStwerk line. As the name suggested (at least for those fluent in German), HANDwerk will clearly showcase Kudoke’s watchmaking expertise, including the Kudoke 1, Kudoke 2 and Kudoke 3. Inspired by Historical British pocket watches, the “Kaliber 1” movement is the focus of Mr. Stefan’s creativity. On the other hand, the KUNSTwerk collection focuses on carved and skeleton elements. KUNSTwerk is the collection that came first, it clearly shows Mr. Stefan’s passion for engraving. With the HANDwerk, specifically the Kaliber 1 movement, Mr. Stefan has moderated the engraved element, making it more balanced in his timekeeping works. For example, with the Kudoke 2, which won the GPHG award in 2019, the morning/evening hour part with two halves of the moon/sun was displayed beautifully and stood out compared to the remaining simple area of the dial.

While the bottom of the watch is a matte finish surrounding the movement bridge, the balance bridge is hand-engraved, and the Ratchet Wheel is spiral-patterned – a very British style, instead of a German movement from Saxon region as we know it.

Step 1: Sketch the engraving with a pen

Next step: Use an awl to create the desired engraving

Detailed images after completion

Experience the carving process

Finishing the ratchet wheel yourself

The ratchet wheel is the top part of the barrel, screwed to the shaft of the barrel. When the watch is wound, the ratchet wheel rotates and tightly winds the mainspring. The task of the ratchet wheel is to transfer energy to the mainspring. And the rattling sound you hear when winding the watch (through the crown) is the sound the ratchet wheel makes.

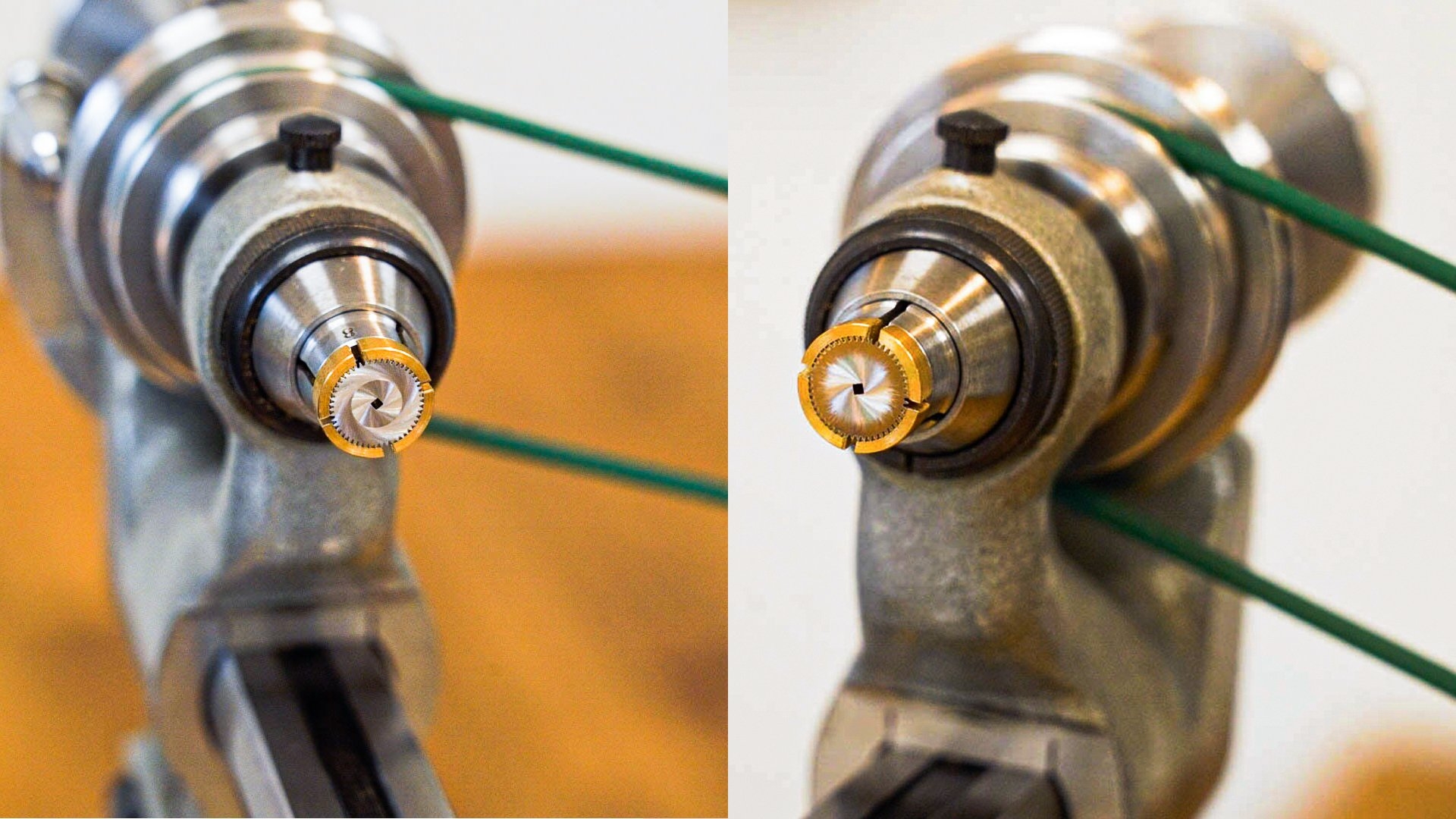

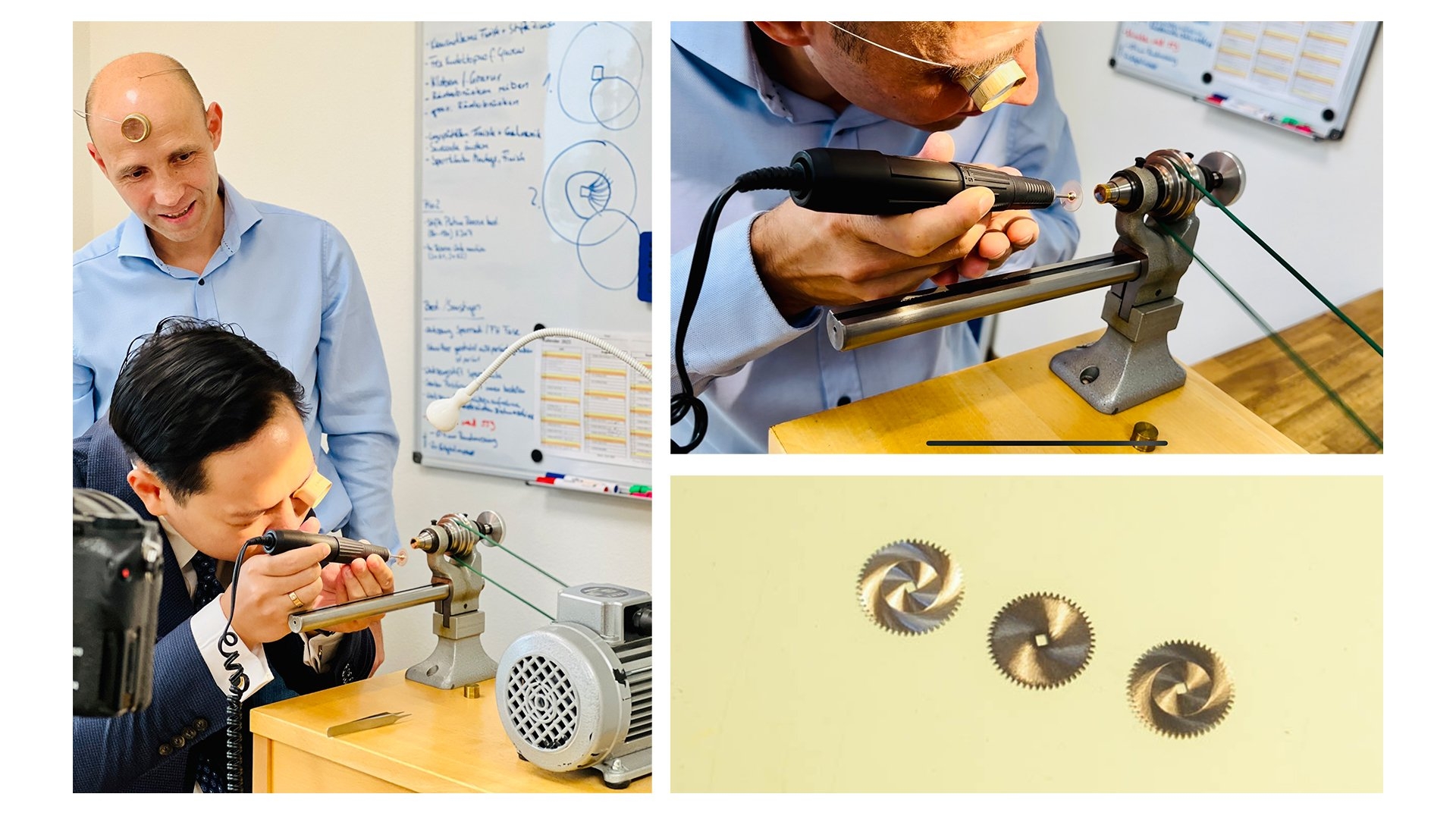

Here are two ratchet images by Mr. Stefan Kudoke and by me. Can you guess which one is Mr. Stefan’s work?

Mr. Stefan Kudoke did every steps to create a complete ratchet wheel: from the newly cut and sawed wheel to the two-layer spiral surface finishing process. As the image drawn by artist Stefan on the whiteboard behind, we need to bring the tool close to the cylinder of the wheel to make the spiral pattern for the first time, then from the edge of the ratchet we create the spiral line floor number 2. In theory it is very simple, but in practice it is extremely hard. In addition to craftsmanship, the artist’s mood combined with luck will create details with high perfection like the pictures you can have a look below. This process is not like traditional industrial production brands, most of the ratchet parts are put into the sunburst finishing machine in quantities of hundreds or even thousands in a short time.

Anglage

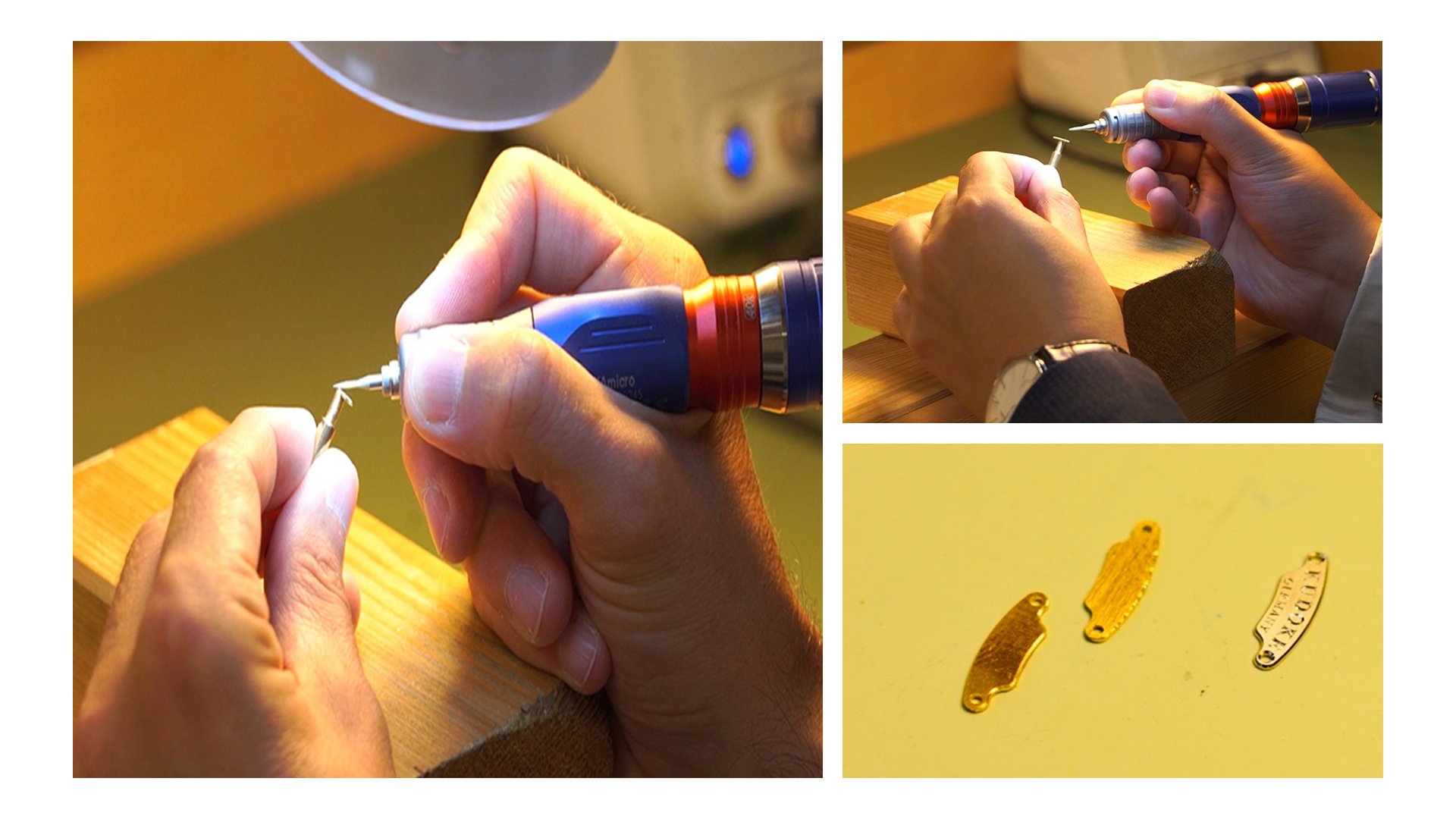

Also Mr. Stefan’s effort to create his own mark in the watchmaking industry is to create as many handmade details as possible. The artisan will spend hours chamfering the machine parts. Chamfering or we can find it more easily with the term “anglage”. In the watch industry, anglage describes a beveled angle or beveling technique. Sure, cutting corners by hand takes a lot of effort. Initially, the watchmaker used a regular beveling machine to file and then polished the components by hand. This is a job that requires honing skills over many years, and according to the art of Stefan Kudoke shared that we also need luck so that the details are completed excellently. Readers, do you recognize where my work is completed?

It sounds like a simple description, but for a watchmaker, chamfering needs to be ensured: the beveled edges are even, of equal width with the two edges running parallel regardless of length. The longer the bezel extends, the more difficult it is for the watchmaker to maintain regularity. Not only must the beveled line around the component be even, but it must also be even with adjacent components and parts. Believe that it is not by accident that these beveled lines appear inside a watch, but it also shows the watchmaker’s own skills.

My experience

In summary, unlike industrial production brands, where machinery and processes make up most of a completed watches, there are still independent watch brands with a production volume of less than 200 watches a year with high craftsmanship, human factors are given top priority like the Kudoke brand. I have learned a lot of knowledge about watches as well as product philosophies from artisan Stefan and his wife Ev Kudoke. I hope to return to Weifa soon on a beautiful sunny day.

Below is the pictures of the Kudoke 2 watch, viewers are invited to admire it:

English

Kiến thức

Nghệ nhân độc lập

Tin tức